Product line-up to increase the reliability of energy management and industrial equipment

Wire electrodes

CT-Wire

(wire electrodes for electric discharge machining)

As a proof of confidence and trust that we do not allow any compromise in wire electrode production quality, we have obtained the quality management system certification(ISO9001) and the environmental management system certification (ISO 14001). Extremely high precision and high processing speed of wire electric discharge machines continue to drive the demand for high precision wire electrodes. In order to meet such needs, we manufacture and sell high quality and high performance CT-Wire products.

A centrally managed production control system and inventory control system ensure appropriate delivery time and low price of ISO9001 certified CT-Wire products.

Advantages of CT-Wire

■ High dimensional accuracy

Products are manufactured with outer diameter accuracy within ± 0.001 mm and roundness within 0.001 mm.

■ Excellent straightness

We strictly perform the test for the number of curls and waves using our original measurement method.

■ Stable mechanical properties

The elongation and maximum tensile strength are strictly inspected by automatic inspection and measuring instruments and controlled to ensure stable quality with little variations.

■ Extremely smooth surface quality

In order to ensure stable high performance of electrode wires, we use wire drawing dies, lubricating liquid and other original control methods. Drawing is always performed in the best conditions, and the surface is finished to remove irregularities, dirt and scratches.

Type

Hard Brass Wire Electrodes (TH series) 60/40

Hard Brass Wire Electrodes (TH)

Type

Hard Brass Wire Electrodes (TH series) 60/40

Hard Brass Wire Electrodes (TH)

| Material | Code | Nominal wire diameterdia. [mm] |

Tensile strength [N/mm2] {kgf/mm2} |

Elongation [%] |

Wire diameterdia. tolerance [mm] |

Roundness [mm] |

|---|---|---|---|---|---|---|

| JIS C2800W | H | 0.10, 0.15, 0.20 | 980 {100} or more | 0.4 or more | ±0.001 | Within 0.001 |

| 0.25, 0.30 | 930 {95} or more |

Type

Hard Brass Wire Electrodes (RH series)

Hard Brass Wire Electrodes (RH)

Type

Hard Brass Wire Electrodes (RH series)

Hard Brass Wire Electrodes (RH)

| Material | Code | Nominal wire diameterdia. [mm] |

Tensile strength [N/mm2] |

Elongation [%] |

Wire diameterdia. tolerance [mm] |

Roundness [mm] |

|---|---|---|---|---|---|---|

| JIS C2700W | H | 0.20 | 980 or more | 0.4 or more | ±0.001 | Within 0.001 |

| 0.25, 0.30 | 930 or more |

Type

High Speed Alloy Wire Electrodes (SH series)

High Speed Alloy Wire Electrodes (SH)

Type

High Speed Alloy Wire Electrodes (SH series)

High Speed Alloy Wire Electrodes (SH)

| Material | Nominal wire diameterdia. [mm] |

Tensile strength [N/mm2] |

Elongation [%] |

Conductivity [%IACS ※] |

Wire diameterdia. tolerance [mm] |

Roundness [mm] |

|---|---|---|---|---|---|---|

| Brass wire with unique composition | 0.20, 0.25, 0.30 | 700 or more | 0.4 or more | 25≤ | ±0.001 | Within 0.001 |

Type

Wire Electrodes for High Speed Machining (EZ Series)

Wire Electrodes for High Speed Machining (EZ)

Type

Wire Electrodes for High Speed Machining (EZ Series)

Wire Electrodes for High Speed Machining (EZ)

| Material | Nominal wire diameterdia. [mm] |

Tensile strength [N/mm2] |

Elongation [%] |

Conductivity [%IACS ※] |

Wire diameterdia. tolerance [mm] |

Roundness [mm] |

|---|---|---|---|---|---|---|

| JIS C2800W | 0.20, 0.25, 0.30 | 900 or more | 2 or more | 22≦ | +0 ~ -0.002 | Within 0.001 |

Type

Wire Electrodes Sale from single reel OK (all series)

Wire Electrodes Sale from single reel OK (all series)

Type

Wire Electrodes Sale from single reel OK (all series)

Wire Electrodes Sale from single reel OK (all series)

| item | Wire diameter | Non-paraffin products | Paraffin products | Weight (kg) |

Bobbin shape |

||

|---|---|---|---|---|---|---|---|

| Product code | Product name | Product code | Product name | ||||

| TH series |

Φ0.10 | 1177211 | CTW-10TH-P5(3)B1 | 1172211 | CTW-10TH-P5(3)SB1 | 3 | P5 |

| Φ0.15 | 1177212 | CTW-15TH-P5(3)B1 | 1172212 | CTW-15TH-P5(3)SB1 | |||

| Φ0.20 | 1177233 | CTW-20TH-P5B1 | 1172233 | CTW-20TH-P5SB1 | 5 | P5 | |

| Φ0.25 | 1177234 | CTW-25TH-P5B1 | 1172234 | CTW-25TH-P5SB1 | |||

| Φ0.30 | 1177235 | CTW-30TH-P5B1 | 1172235 | CTW-30TH-P5SB1 | |||

| Φ0.20 | 1177323 | CTW-20TH-P10B1 | 1172323 | CTW-20TH-P10SB1 | 10 | P10 | |

| Φ0.25 | 1177324 | CTW-25TH-P10B1 | 1172324 | CTW-25TH-P10SB1 | |||

| Φ0.30 | 1177325 | CTW-30TH-P10B1 | 1172325 | CTW-30TH-P10SB1 | |||

| RH series |

Φ0.20 | 1179233 | CTW-20RH-P5B1 | 1178233 | CTW-20RH-P5SB1 | 5 | P5 |

| Φ0.25 | 1179234 | CTW-25RH-P5B1 | 1178234 | CTW-25RH-P5SB1 | |||

| Φ0.30 | 1179235 | CTW-30RH-P5B1 | 1178235 | CTW-30RH-P5SB1 | |||

| Φ0.20 | 1179323 | CTW-20RH-P10B1 | 1178323 | CTW-20RH-P10SB1 | 10 | P10 | |

| Φ0.25 | 1179324 | CTW-25RH-P10B1 | 1178324 | CTW-25RH-P10SB1 | |||

| Φ0.30 | 1179325 | CTW-30RH-P10B1 | 1178325 | CTW-30RH-P10SB1 | |||

| SH series |

Φ0.20 | 1173233 | CTW-20SH-P5B1 | 5 | P5 | ||

| Φ0.25 | 1173234 | CTW-25SH-P5B1 | |||||

| Φ0.30 | 1173235 | CTW-30SH-P5B1 | |||||

| Φ0.20 | 1173323 | CTW-20SH-P10B1 | 10 | P10 | |||

| Φ0.25 | 1173324 | CTW-25SH-P10B1 | |||||

| Φ0.30 | 1173325 | CTW-30SH-P10B1 | |||||

| EZ series |

Φ0.20 | 1026233 | CTW-20EZ-P5 | 5 | P5 | ||

| Φ0.25 | 1026234 | CTW-25EZ-P5 | |||||

| Φ0.30 | 1026235 | CTW-30EZ-P5 | |||||

| Φ0.20 | 1026463 | CTW-20EZ-P20 | 20 | P20 | |||

| Φ0.25 | 1026464 | CTW-25EZ-P20 | |||||

| Φ0.30 | 1026465 | CTW-30EZ-P20 | |||||

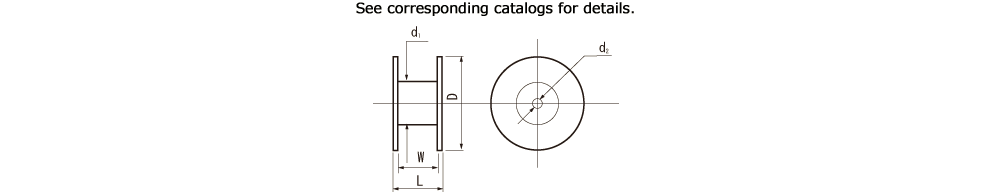

Bobbin shape

Bobbin shape

| Bobbin shape code | Flange diameterdia. D | Barrel diameterdia. d1 | Outer width L | Inner width W | Shaft hole diameterdia. d2 | TH | RH | SH | EZ |

|---|---|---|---|---|---|---|---|---|---|

| P3 | 130 | 80 | 110 | 90 | 20 | ○ | × | × | × |

| P5 | 160 | 90 | 114 | 90 | 20 | ○ | ○ | ○ | ○ |

| P10 | 200 | 90 | 134 | 110 | 25 | ○ | ○ | ○ | × |

| P15 | 200 | 90 | 134 | 110 | 25 | ○ | × | × | × |

| P20 | 250 | 110 | 140 | 110 | 34 | ○ | ○ | ○ | ○ |

| DP30 | 280 | 200 | 220 | 180 | 73 | ○ | × | ○ | × |

| D160 | 160 | 100 | 160 | 128 | 22 | ○ | × | × | × |

| D200 | 200 | 125 | 200 | 160 | 25 | ○ | × | × | × |