Product line-up for more reliable energy management and industrial equipment

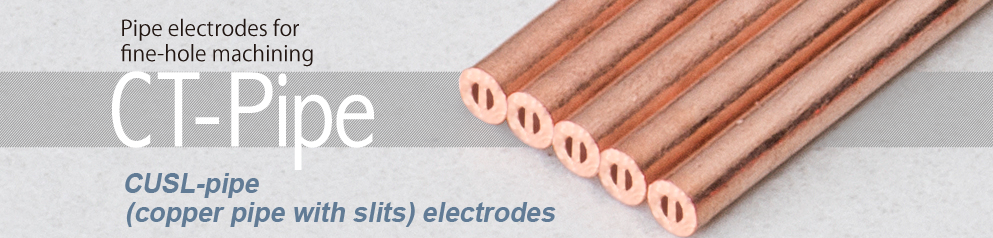

Pipe electrodes

CT-Pipe

(pipe electrodes for fine-hole machining)

CT-Pipe electrodes are already in wide use alongside spreading-wire electric discharge machines for start-hole drilling in the latter and part processing in fine-hole drilling machines.

Advantages of CT-Pipes

They achieve excellent straightness, which is also strictly checked using our original inspection methods. The holes at both ends are free of all burrs and corrosion, etc.

Electrode specifications (for inner and outer diameters) are set in advance based on a processing performance test and we manufacture and sell products with minimal variation thanks to thorough quality control.

1. Advantages of slit (SL)-pipe electrodes

1) Pipe electrodes with slits have been developed for fine-hole machining. They feature rotating electrodes capable of boring holes that leave no internal core behind, paving the way for stable and deep hole-boring with minimal variation in diameter.

2) Since electrodes with slits are stronger than single-hole pipes, they are ideal for high-precision-hole machining with low electrode consumption, even for deep holes. (Generally, when drilling deep holes as long as 100x electrode outer diameter, the electrode consumption is below 0.1 mm)

2. The processing performance of Cu- & Bs-pipe electrodes differs significantly, even under identical processing conditions, depending on the size and variation of the inner diameter.

1) Results of comparative tests with Cu-pipes of 0.5φ x 300L show that electrodes with inner diameters of 0.18φ have a machining speed 3.2 times higher and an electrode consumption rate of half or less compared to electrodes of 0.20φ.

2) While processing performance naturally depends on the power source, electrical conditions, working liquid, hydraulic pressure and other factors related to fine-hole drilling machines, we leverage many years of accumulated experience and technologies to manufacture and sell products with optimal specifications.

3) We offer high-quality CT-pipe electrodes with excellent straightness, true to our motto of maximum speed and low wear rate.

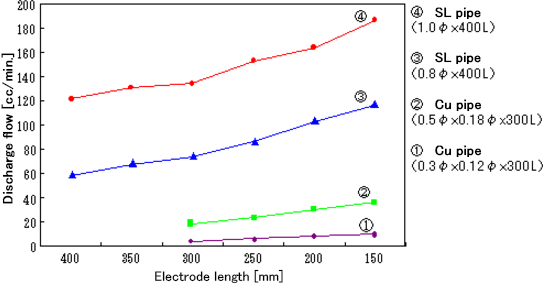

3. Relationship between electrode length and discharge flow rate

1) The discharge flow rate decreases proportionally with increasing electrode length, while the slope remains unchanged, regardless of the hydraulic pressure.

2) Since the flow rate of liquid discharged from the pipe electrode is an important factor to ensure stable processing, the standard electrode lengths are set to 300 and 400 mm respectively.

3) Extended electrodes 500 mm long or more are also available for drilling ultra-deep holes and if reclamping is performed during drilling, flow correction and anti-deflection measures can be applied to improve, the drilling stability.

Please contact us for any dimensions and shapes not mentioned in the product list.